Material and surface analyses are essential in functional surface coating, as they enable a precise assessment of material properties and coating quality. The analyses carried out ensure that the coating meets specific requirements and operating conditions. The measurement methods that Betz-Chrom performs in-house for quality assurance are listed below. Material and surface analyses can also be commissioned as a service. For more extensive analyses and tests, we cooperate with specialised testing institutes.

Request your individual quote now

– fast, accurate and with technical consultation.

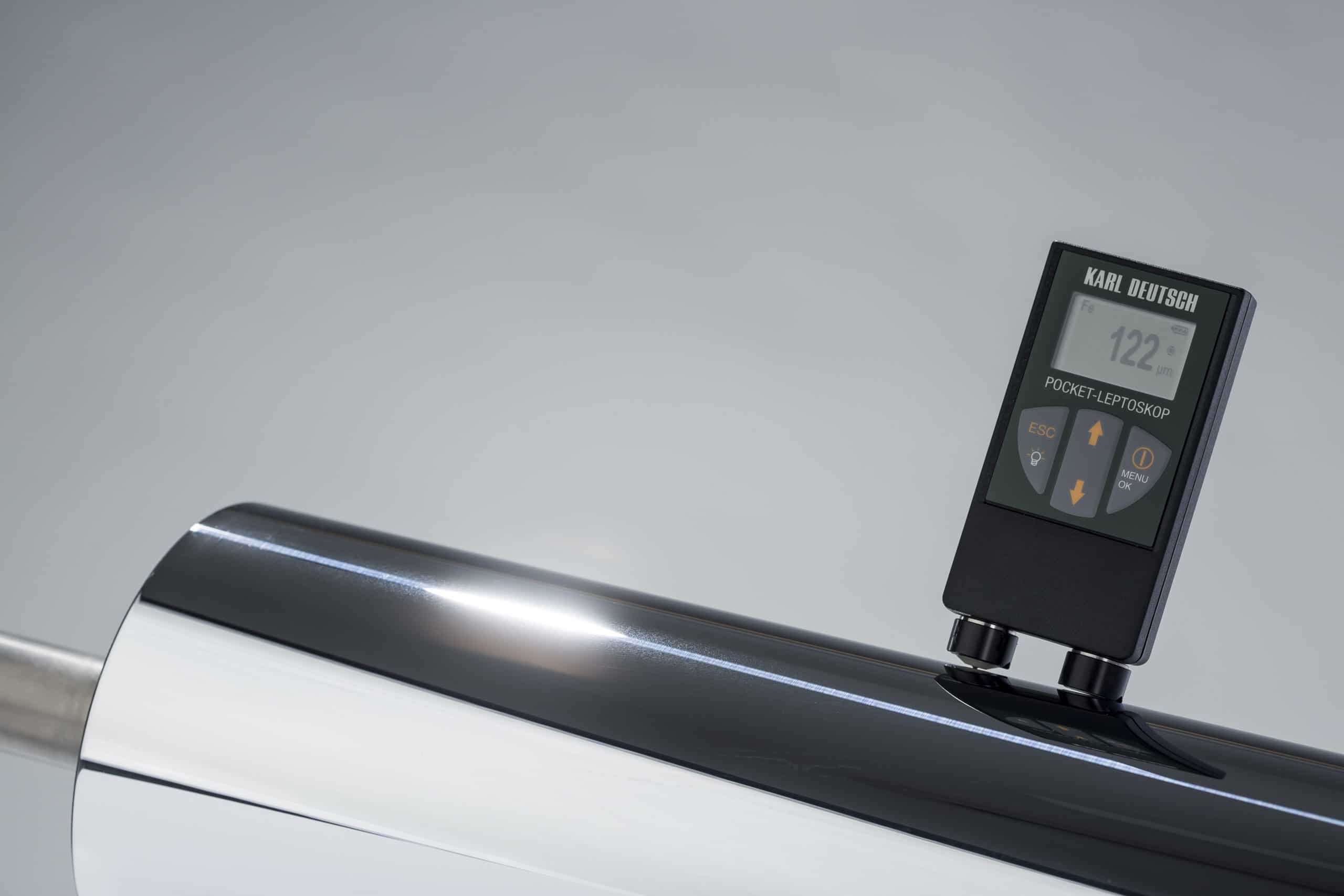

Coating thickness determination

Determining the coating thickness is essential for functional surface coatings to ensure that the coating provides the required protective and functional properties such as corrosion resistance and wear resistance. A layer that is too thin may not fully deliver the desired effect, whereas a layer that is too thick can lead to mechanical problems or unnecessarily high costs.

| Test characteristic | Magnetic induction measurement according to DIN EN ISO 2178 | Eddy current measurement according to DIN EN ISO 2360 | X-ray fluorescence analysis (XRF) | Visual inspection of the cross-section |

| Material | Non-magnetic coatings on magnetic substrate | Electrically insulating (non-conductive) coatings on metallic (conductive), non-magnetic substrate | Various materials possible; due to the available equipment only measurements of chrome on steel are performed | Suitable for almost all coatings and substrates |

| Coating thicknesses | 0,1 µm – 1 mm | 0,1 µm – 1 mm | 0,1 µm – 60 µm | unlimited |

| Destructiveness | non-destructive | non-destructive | non-destructive | destructive |

Vickers hardness test according to ISO 6507 / ASTM E384

Hardness measurement is an essential part of quality control in functional surface coating, as it provides information about the mechanical resistance of the layer to abrasion, wear and scratches.

- Suitable for various materials

- Hardness measurement on the stationary test stand is very precise but destructive

- Hardness measurement with a mobile device is less accurate but non-destructive

Testing of materials and chemical compositions using X-ray fluorescence (XRF)

Determining material composition by means of X-ray fluorescence is useful for a wide range of applications. Material analysis can reveal material defects that can lead to problems with coating adhesion. Precise measurement of the layer composition, e.g. the phosphorus content in electroless nickel-phosphorus layers, ensures the desired properties of the coating system. When repairing worn components, it is often necessary to determine the material composition if no technical drawings are available.

- Suitable for various materials

- Non-destructive

Surface analysis using a digital microscope

Surface analysis using a digital microscope enables a detailed examination of coatings and materials through surface magnification and high-resolution imaging. Precise measurements of irregularities and the analysis of cracks in plan view make it possible to capture topographical structures and identify defects and material deviations.

- Suitable for various materials

- Non-destructive

Surface analysis using a roughness tester

Surface analysis using a perthometer serves to measure the roughness of a surface precisely. The mechanical tracing device guides a fine stylus over the material to record height differences and irregularities. This method provides detailed information about the surface structure, such as the arithmetic mean roughness (Ra), the mean depth of roughness (Rz), the total profile height (Rt) and other relevant roughness values.

- Suitable for various materials

- Non-destructive

Surface analysis using cross-section grinding

Surface analysis using cross-section grinding allows a detailed examination of the internal structure of coatings and materials by preparing a cross-section to visualise layer thickness, microstructure and potential defects such as pores or cracks. During crack analysis in the cross-section, the frequency, length and width of the cracks can be analysed, providing valuable information about the technical properties of the coating.

- Suitable for various materials

- Destructive

Gloss measurement

The gloss measurement of electroplated coatings using an optical gloss meter (reflectometer) employs laser light to measure the intensity of the reflected light on the coating surface, thereby objectively determining the gloss level. This method provides precise information on surface quality and uniform reflection, which is particularly important in decorative and functional applications of electroplated coatings.

- Suitable for various materials

- Non-destructive