Various surface qualities are required in the printing and foil industries. Rough matte chrome surfaces have an optimal grip, which improves the conveyability of feed rolls. If, on the other hand, a high-gloss surface is desired, we process the hard chrome surface up to mirror finish. In general, the hard chrome layer is characterized by its anti-adhesive properties, which prevent “sticking” or “caking” on the rollers.

The optimum surface quality

Matte hard chrome

In order to achieve a structured surface, the workpieces are blasted before the coating process. Blasting creates the specified peak-to-valley height. After the surface finishing, the components have a structured hard chrome layer and stand out visually through a matt surface. Via the defined peak-to-valley height the grip of feed rollers can be controlled for example. Learn more about our blasting process.

Mirror finish

With the Superfinishing procedure, a surface quality up to mirror finish can be created. Very fine Finish tapes (up to 3 µm) are used for this purpose. Mirror finish is required if the use of the component requires an absolutely homogeneous, clean and smooth surface. Learn more about the superfinishing process.

Betz-Chrom acts in accordance with EU Regulation (EC) No. 1907/2006 (REACH) of 18 December 2006 as the holder of an authorisation for the use of chromium trioxide. You can find more detailed information on REACH, our authorisation and our activities for alternative research under FAQ on REACH.

Properties of the hard chrome layer:

- Layer thickness: 0.003 to 0.500 mm

- Hardness: > 850 HV 0.1

- Roughness: Rmax < 0.1 μm to Rz 70 μm

- lead and cadmium free (RoHS compliant)

Request your individual quote now

– fast, accurate and with technical consultation.

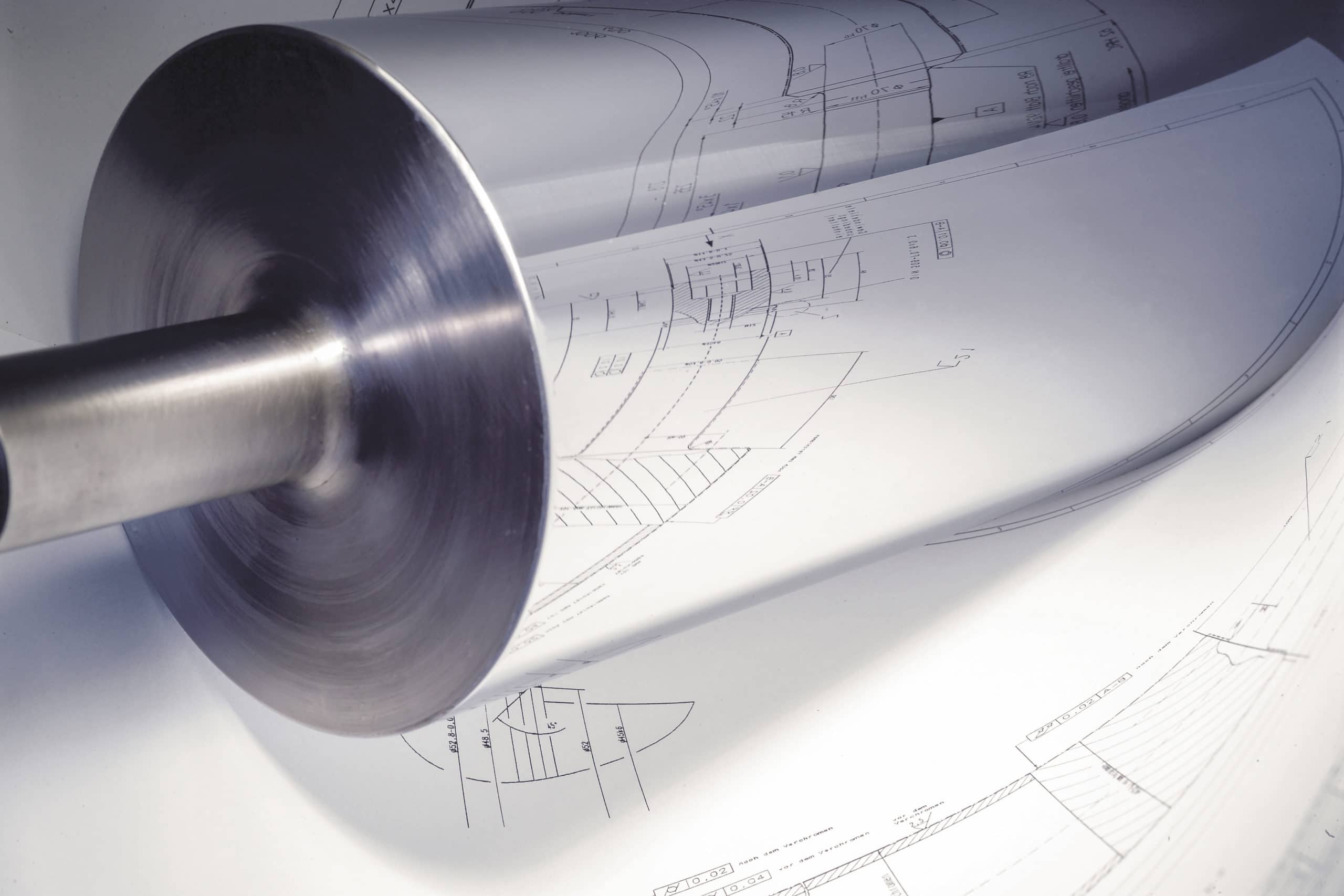

Component examples for hard chrome plating

Examples from the foil industry

Mirror rollers, mirror screws, engraved rollers, spiral mandrel distributors, embossing rollers, heating and cooling rollers, drive rollers, nozzles and mandrels

Examples from the printing industry

Printing and plate cylinders, dampening distribution cylinders, duct rollers, metering rollers, feed rollers

Learn more about our hard chrome processes.

Dimensions of your components:

- Vertical chrome plating: ⌀ 1300 x 4700 mm or 8000 mm on envelope

- Horizontal chrome plating: ⌀ 60 x 6500 mm

- Shapes: 1700 x 1500 x 1300 mm

- Weight: 5000 kg