Our strengths

Dimensions & more

roughness & special contours

Small to large

Grinding length up to 4000 mm

Single part to series

conventional or CNC

Certified quality

DIN EN ISO 9001

Technical advice

Competent & on equal terms

Betz-Chrom specializes in external cylindrical grinding between centers. With state-of-the-art machinery, many years of experience and the utmost care, we machine rotationally symmetrical components – precisely in the μm range, cost-effectively and with repeat accuracy. Whether individual parts or series: our customers rely on the highest dimensional accuracy, the finest surface finishes and technical advice based on partnership. Trust in quality that fits – in the truest sense of the word!

Specifications of our grinding shop

Procedure

External cylindrical grinding between centers

Dimensions

max. Ø 850 x 4000 mm

Weight

max. 3000 kg

Control

Conventional or CNC grinding

Surface roughness

Ra 0.2 µm, Rz 0.8 – 4.3 µm

Cylindricity and concentricity:

Cylindricity ≥ 0.01 mm, concentricity ≥ 0.005 mm

Request your individual quote now

– fast, accurate and with technical consultation.

External cylindrical grinding:

Our areas of application

Contract manufacturing

External cylindrical grinding from single production to series production: Depending on the requirements, components are machined on conventional or repeat-accurate CNC grinding machines. We achieve precise dimensional tolerances and surface qualities efficiently and accurately. External cylindrical grinding between centers is also suitable for correcting geometric errors in mechanical parts.

Cylindrical grinding of hard chrome surfaces

In surface coating, precision grinding is an important process step in order to optimize the surface quality. As an upstream process step, the surface of the base material is ground to improve the coating quality. As post-processing step, cylindrical grinding achieves the desired surface finish. In the case of thicker hard chrome layers, components are chrome-plated with excess and then ground to the specified dimension. This appies to components that require particularly high wear protection.

Cylindrical grinding for repairs

In combination with our mechanical processing, excess chrome plating is also suitable for the repair or overhaul of worn components.This process can be used, for example, to repair cylinders, piston rods and turbines. a cost-effective and resource-saving alternative to purchasing new parts. Learn more about the benefits of reconditioning.

Beyond cylindrical grinding:

Our cooperation network for complete production

With our cooperation platform we can offer you the complete manufacturing of components for machine and plant engineering, such as roller tubes, shell tubes, piston rods, etc. all from a single source. As a component supplier, our services cover all desired process steps, including material ordering, turning, centering, grinding, coating through to the delivery of the finished components.

Individual processing steps, such as internal cylindrical grinding, surface grinding, flat grinding, etc., can also be commissioned. We will organize the processing through our cooperation network.

Service

One contact person for all orders

Time

Elimination of coordination activities

Costs

Reduction of warehousing costs

Quality

Fulfill your quality requirements

Delivery reliability

Reliable delivery performance

What is cylindrical grinding?

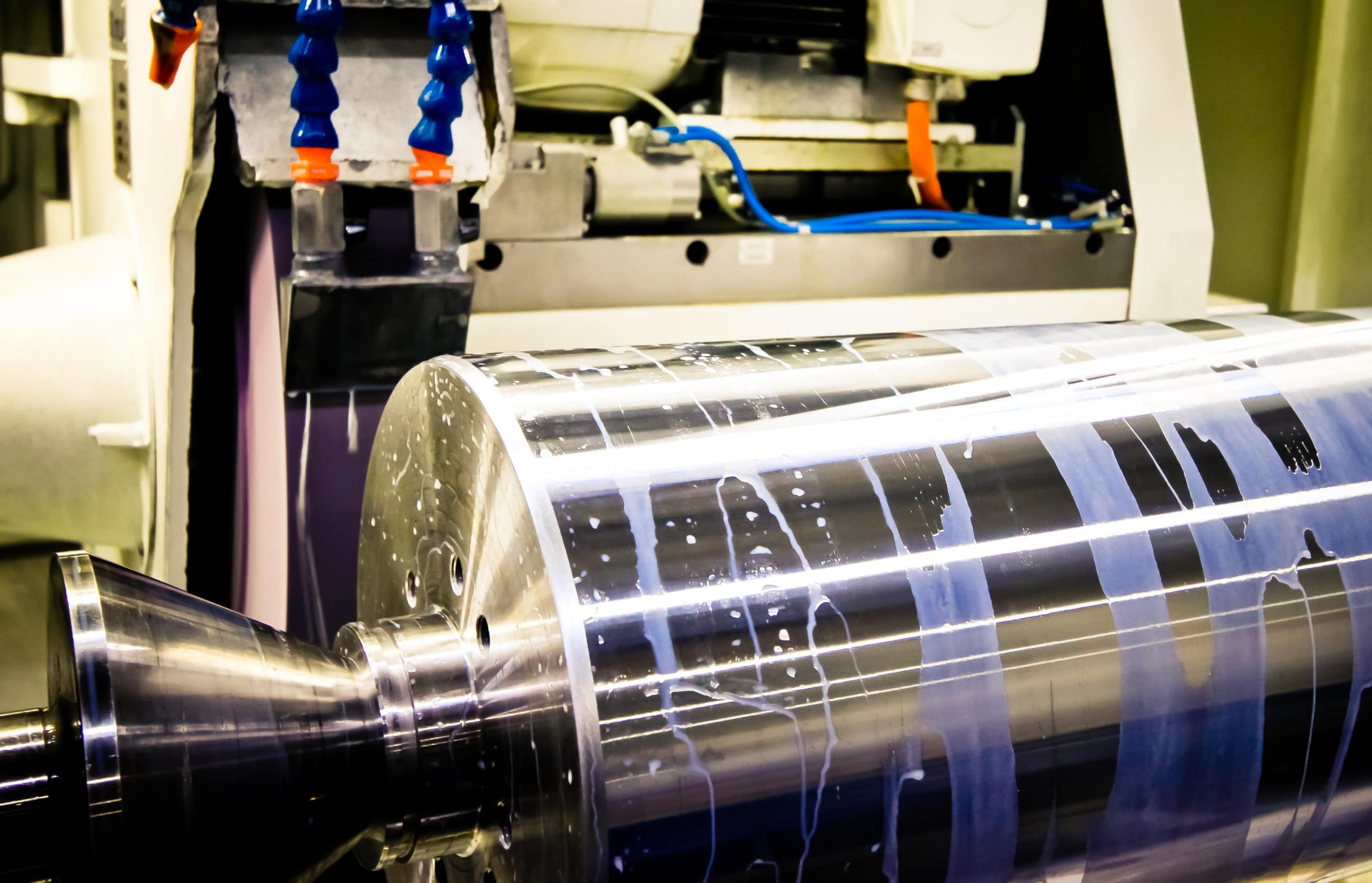

In cylindrical grinding, the workpiece is clamped between two centers and rotates around its own axis during the grinding process.

This process is used for workpieces that require high dimensional and shape accuracy over the entire length. The grinding wheel is guided radially against the rotating workpiece and removes material to create the desired surface and shape.

Typical for cylindrical grinding between centres is the fixation of the workpiece in the axial direction. This prevents slipping and achieves reproducible machining quality, especially for series parts.

The centering points on the end faces of the workpiece must be prepared precisely, as they are crucial for concentricity and precision. This process is ideal for components such as shafts, axles or bolts that require high roundness and tight tolerances.

The processing quality is optimized through the use of different abrasives, machine configurations and coolants. Modern CNC cylindrical grinding machines enable automated, high-precision machining.

External cylindrical grinding between centers

External cylindrical grinding is a high-precision grinding process for machining the cylindrical outer surfaces of rotationally symmetrical workpieces such as shafts, axles or bolts.

The workpiece is rotated around its own axis and guided against a rotating grinding wheel. This process allows very tight tolerances, exact cylinder shapes and the finest surface roughness to be achieved.

Typical applications can be found in the automotive industry, in mechanical engineering or in the manufacture of hydraulic components. External cylindrical grinding is suitable for both single part and series production and is indispensable for components with high dimensional accuracy and roundness requirements.

A decisive advantage of external cylindrical grinding is the ability to clamp workpieces between centers and thus achieve a particularly high level of shape accuracy over the entire length.

In modern CNC cylindrical grinding machines, the grinding parameters can be precisely controlled and reproduced. Betz-Chrom offers professional external cylindrical grinding with high process reliability and reproducible quality – ideal for demanding industrial applications.

Process sequence & typical tolerances

The workpieces to be ground are usually supplied in the form of blanks or pre-machined parts with a defined allowance.

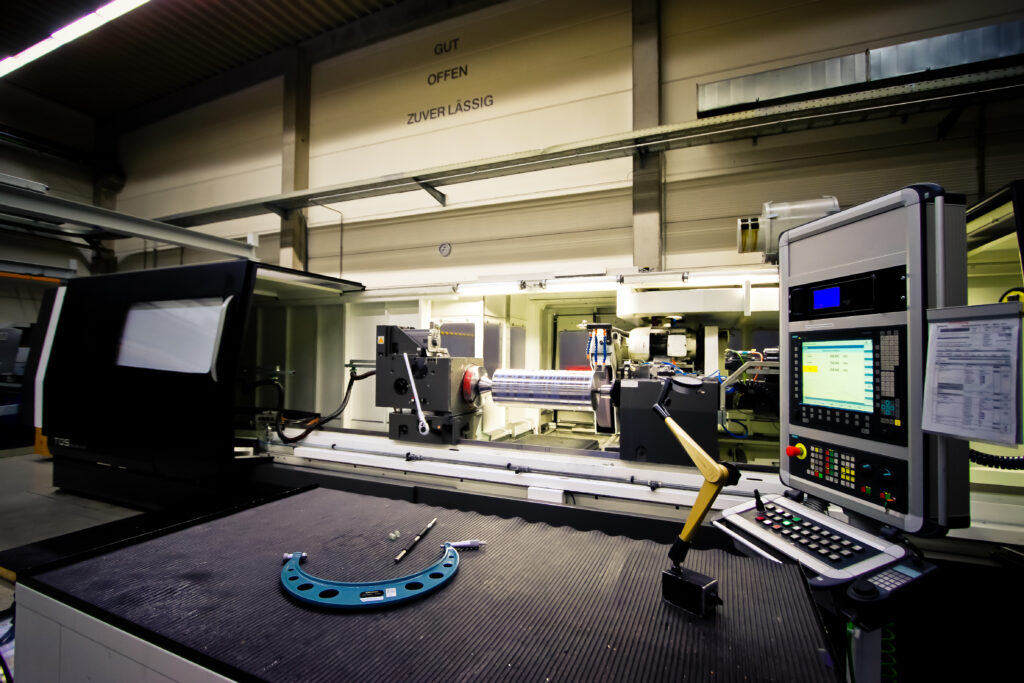

After receipt, the workpieces are carefully checked and documented. The preliminary dimensions are recorded using precise measuring equipment such as micrometers in order to ensure sufficient dimensions for the grinding process.

The machine is then prepared: the grinding wheel is selected, dressed if necessary and the workpiece clamping between the centers is adjusted. The grinding parameters such as feed rate and cutting speed are also set depending on the material and processing task.

After setting up, the actual grinding process begins. The workpiece is constantly rotated against the rotating grinding wheel, which gradually removes material. The process is cooled to prevent thermal distortion.

After grinding, the final dimensions are checked. Depending on the requirements and workpiece, typical manufacturing tolerances for cylindrical grinding are in the range of 0.005 mm for concentricity. All standard ISO tolerances/fits can be manufactured for final dimensions..

Advantages and disadvantages of cylindrical grinding between centers

High dimensional and shape accuracy: Clamping the components enables an exact cylinder shape with precise concentricity properties to be achieved.

Very good surface quality: Roughness values of Ra 0.2 µm and Rz 0.8 – 4.3 µm can be achieved.

Repeat accuracy: Thanks to the defined clamping position, the components in a series can be processed reproducibly.

Suitable for various component dimensions: With our machine diversity, we process small and large components with dimensions of up to Ø 850 x 4000 mm.

Simple reworking and checking: If necessary, a workpiece can be clamped again and reground without losing its position.

Complex clamping preparation: The centering at the workpiece ends must be made very precisely. Errors directly affect the grinding quality.

Limited flexibility for workpiece shapes: Only rotationally symmetrical, elongated parts with accessible end faces can be machined between centers.

Set-up time required: Setting up the machine and precise alignment require experience and care.

Not suitable for very short or bulky components: These often cannot be clamped stably between centers and require other grinding methods (e.g. centerless grinding).

Other frequently asked questions about cylindrical grinding

What is the difference between external cylindrical grinding, internal cylindrical grinding and centerless cylindrical grinding?

Cylindrical grinding is a precise machining process for processing rotationally symmetrical workpieces with high dimensional and shape accuracy. Different processes are used depending on the requirements.

In external cylindrical grinding between centers, the cylindrical outer surfaces of rotationally symmetrical workpieces are machined. The workpieces are clamped between centers.

Internal cylindrical grinding is used to machine cylindrical internal contours, e.g. bushings, bearings or hydraulic components.

In centerless cylindrical grinding, the workpiece is ground without fixed clamping. The workpiece is guided by an infeed roller and a guide rail.

What all cylindrical grinding processes have in common is the aim of achieving maximum precision and repeat accuracy.

When is grinding used over other machining processes such as turning or milling?

Grinding of metal surfaces is used when the requirements for dimensional accuracy, surface quality or hardness of the material go beyond what can be achieved economically or technically by turning or milling. Tolerances in the µm range can be achieved due to the high dimensional and shape accuracy of grinding. Grinding can also be used to achieve special surface quality requirements such as very smooth or mirror-like surfaces with low roughness values. Grinding is therefore often used as a finishing process after milling or turning. Hard materials such as hardened steel and hard metals are difficult or even impossible to machine economically using turning and milling. However, by choosing the right grinding tools, such as CBN or diamond wheels, even hard materials can be machined economically.

Why is edge rounding and applying chamfers to sealing surfaces so important?

The targeted rounding of edges and application of chamfers is crucial for components such as shafts or hydraulic rods – especially in areas where sealing systems such as O-rings, lip seals or sleeve seals are used.

Sharp-edged transitions can damage the sensitive sealing lips during installation or lead to increased wear and leaks during operation. By softening the edges, the risk of tears, indentations or leaks is significantly reduced.

An even chamfer also makes it easier to install the sealing elements and improves their guidance behavior during operation. Targeted edge rounding therefore makes a significant contribution to the durability and functionality of sealing systems, particularly in hydraulic and pneumatic applications.

Does Betz-Chrom also carry out centerless cylindrical grinding and internal grinding?

Betz-Chrom specializes in high-precision external cylindrical grinding between centres. For this purpose, we have optimally coordinated machinery and an experienced, highly qualified team. Processes such as centerless cylindrical grinding or internal grinding are not part of our own production portfolio.

However, thanks to our proven cooperation network, we can also offer you these processing services – in collaboration with long-standing, qualified partner companies that work according to our quality standards. This means you receive all services reliably from a single source.

What does a CNC grinder or cylindrical grinder do?

The profession of CNC grinder or cylindrical grinder is a high-precision and responsible field of activity in the metalworking industry.

The focus is on setting up, operating and monitoring CNC-controlled cylindrical grinding machines, which are used to grind rotationally symmetrical workpieces such as shafts, cylinders or pistons to the highest dimensional accuracy and surface quality.

The tasks include selecting suitable grinding wheels, precisely aligning the workpieces and setting the grinding parameters such as infeed, feed and cutting speed – often in the range of a few micrometers.

Another key component is quality control: using measuring equipment such as micrometers, touch probes or coordinate measuring devices, the grinder checks intermediate and final dimensions and documents the results.

Experience, precision and a good feel for materials and tolerances are essential in this profession in order to meet the high requirements for dimensional accuracy, surface quality and repeat accuracy – especially in sensitive sectors such as mechanical engineering, hydraulics, aviation and medical technology.

Express service

For orders with increased deadline pressure, you have the option of using our express service. This is agreed upon in direct consultation with our production control and charged via a surcharge.

Initial sampling

Before starting more complex series, we offer you an initial sampling at discounted rates. Here you can convince yourself of the quality of our processing. In addition, together we ideally coordinate our production processes.

Tips for delivery

For optimum quality and short lead times in our production, the delivery condition of the components is one of the decisive factors. Here you will find helpful tips for the delivery of your components.