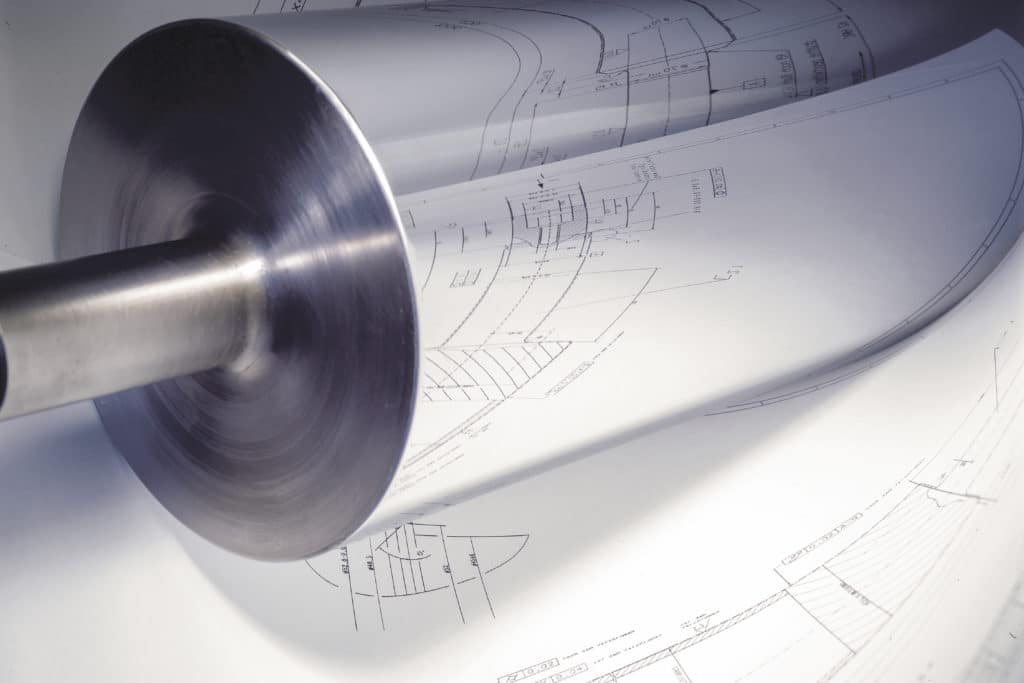

polishing

Durable. Efficient. High quality.

1,000+ industrial customers already trust our production technology.

Our strengths

Defined surfaces

material ratio & roughness

Small to large

Length up to 3600 mm

Single part to series

tailored to your requirements

Flexible procedures

depending on the surface quality

Certified quality

DIN EN ISO 9001

The combination of belt grinding and polishing ensures dimensionally accurate, smooth and durable metal surfaces. With a wide range of machinery, many years of experience and the utmost care, we process rotationally symmetrical components – precisely, economically and with repeat accuracy. Whether individual parts or series: our customers rely on the finest surface finishes and technical advice based on partnership. Trust in quality that shines – in the truest sense of the word!

Production specifications Polishing

Procedure

polishing

Dimensions

max. Ø 480 x 3000 mm

Weight

max. 2000 kg

Control

Conventional

Surface roughness

Ra ≥ 0.25; Rz ≥ 1.6

Recording

Between peaks

Production specifications for belt grinding

Procedure

Belt grinding

Dimensions

max. Ø 600 x 3600 mm

Weight

max. 2000 kg

Control

Conventional

Surface roughness

Ra ≥ 0.3; Rz ≥ 1.7

Recording

Between peaks

Request your individual quote now

– fast, accurate and with technical consultation.

Polishing:

Our areas of application

Belt polishing

Industrial polishing or belt polishing can also be carried out as a pre- and post-processing step. After hard chrome plating, industrial polishing improves the appearance and functionality of the chrome layer. The functional advantages of industrial polishing are the reduction of friction and the increase in corrosion resistance.

Teflonizing or TSI is a variant of post-treatment. The micro-cracked chrome surface is sealed with a Teflon coating. Teflon coating can temporarily increase the corrosion resistance.

Belt grinding

Belt grinding is used as a pre- and post-processing method. Before hard chrome plating, it creates an even and smooth substrate for optimum adhesion of the chrome layer.

Belt grinding reduces the roughness of the surface, resulting in a uniform, glossy and functionally optimized surface.

Process flow

The machining process begins with the selection of the appropriate process – depending on the material, component geometry and desired surface quality.

As a rule, the workpieces are clamped between centers and set up for the specific process.

The component is processed with a circumferential grinding belt. This process is primarily used for smoothing, removing burrs or preparing for coatings. It produces an even surface with good adhesion.

Polishing is carried out as pre- or post-processing. The surface is smoothed and refined using polishing belts or pastes. The aim is to achieve a visually appealing surface with reduced friction and – depending on the application – improved corrosion protection.

Furthermore, the superfinishing process is possible as the highest level of fine machining. Here, a fine abrasive belt is guided in an oscillating motion onto the rotating component. The result is an extremely smooth surface with a high bearing ratio and a uniform cross-hatch pattern – ideal for components subjected to tribological loads or for precise bearing and sealing surfaces.

In all processes, the surface is finally checked, measured if necessary and the component is carefully packaged.

Depending on the quality requirements, the processes can be used individually or in combination.

Beyond polishing:

Cooperation network / additional services

With our cooperation platform we can offer you the complete manufacturing of components for machine and plant construction, such as roller tubes, shell tubes, piston rods, etc. from one provider. As a component supplier, our service for you includes all the requested process steps, including material ordering, turning, centering, grinding, coating through to the delivery of the finished components.

In collaboration with our experienced cooperation partners, we also offer you individual machining processes such as internal cylindrical grinding, surface grinding and flat grinding, etc.

Service

One contact person for all orders

Time

Elimination of coordination activities

Costs

Reduction of warehousing costs

Quality

Fulfill your quality requirements

Delivery reliability

Reliable delivery performance

Other frequently asked questions about polishing

What is the difference between polishing and superfinishing?

Polishing uses polishing belts or pastes to smooth and refine the metal surface. Superfinishing, on the other hand, uses oscilliation to create a defined contact area, optimizing lubricant film distribution and tribological properties.

What is the main benefit of polishing

Polishing produces smooth, shiny surfaces, reduces friction and improves the visual appearance and, thanks to TSI post-treatment, corrosion resistance – especially after galvanic coatings such as hard chrome.

Can surfaces be polished without a coating?

Yes, polishing and superfinishing are possible regardless of a coating. They can be used on uncoated base materials as well as on already coated surfaces (e.g. hard chrome).

What is belt grinding typically used for?

Belt grinding is particularly suitable for preparing surfaces – before coating or polishing, for example. It is used to remove burrs, create a uniform structure and improve adhesion for subsequent processes.

What are the advantages of polishing and belt grinding?

Optimum surface quality

Reduced coefficient of friction

Longer service life of components

Improved lubricant distribution

Removal of processing marks

→ Removes burrs, grooves and other residues from previous processing steps.

Express service

For orders with increased deadline pressure, you have the option of using our express service. This is agreed upon in direct consultation with our production control and charged via a surcharge.

Initial sampling

Before starting more complex series, we offer you an initial sampling at discounted rates. Here you can convince yourself of the quality of our processing. In addition, together we ideally coordinate our production processes.

Tips for delivery

For optimum quality and short lead times in our production, the delivery condition of the components is one of the decisive factors. Here you will find helpful tips for the delivery of your components.