Industrial polishing and superfinishing processes are used to produce the desired surface quality. It is a fine form of mechanical processing to improve the surface roughness and to produce the specified bearing ratio. Whereas dimensional requirements for a component are implemented by precision grinding. In principle, all processes can also be requested independently of a surface coating.

Belt polishing

Belt polishing or industrial polishing is one of the machining procedures. The choice of grit determines the peak-to-valley height.

As a processing step before chrome plating, polishing is suitable to mechanically remove heavily scaled residues on the component. As standard, the workpieces are polished after chrome plating in order to achieve the desired surface quality.

Teflon coating is a variant of the post treatment. The micro-cracked chrome surface is sealed with a Teflon coating. Teflon coating can temporarily increase the corrosion resistance.

- Maximum dimensions: Ø 850 x 3600 mm

- Weight: max. 2000 kg

- Roughness: Rz 1.6 – 2.5

- Between peaks

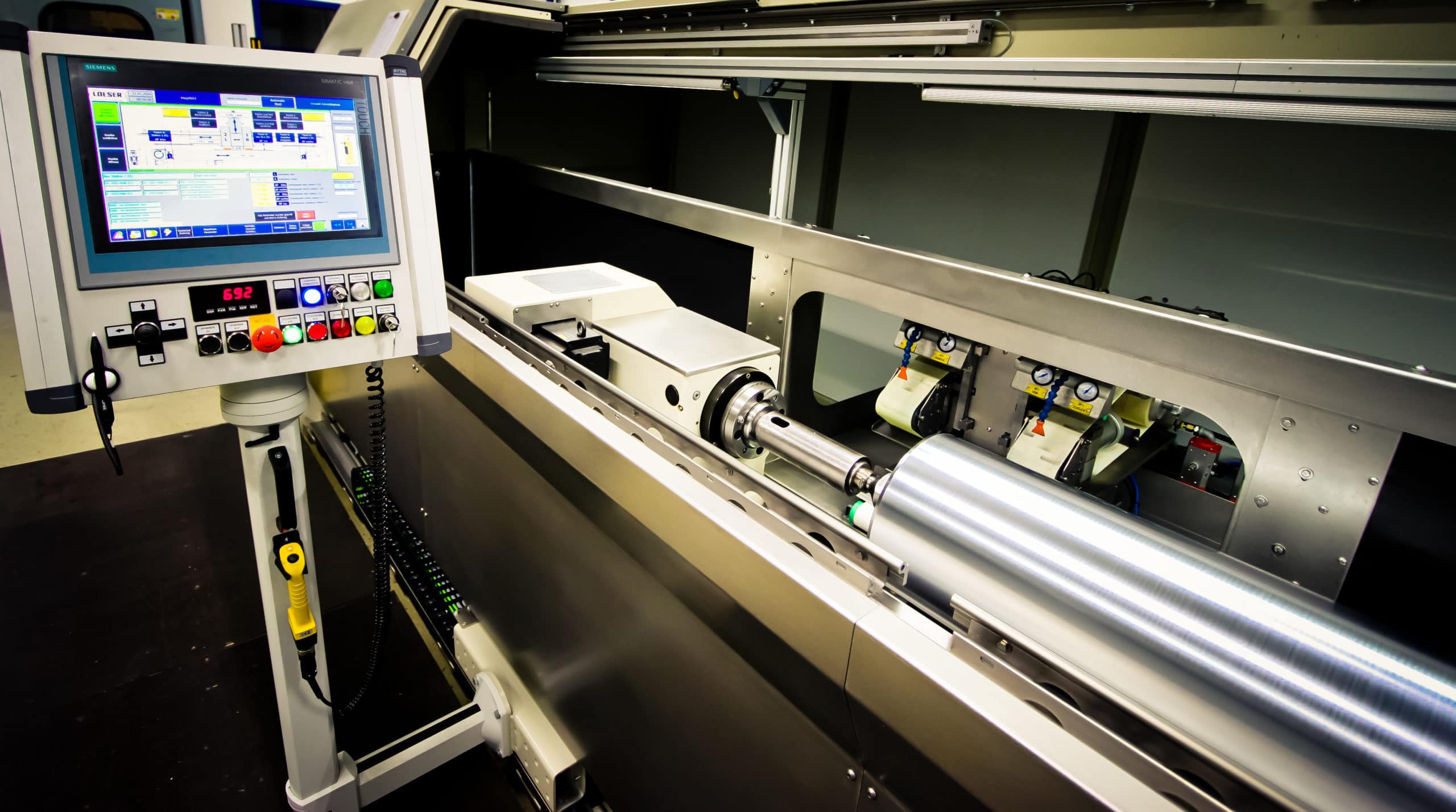

Superfinishing

Superfinishing (microfinish) optimizes the surface structure in the micro range. The Superfinishing process increases the bearing ratio and thus the compacting area. In order to achieve the desired contact area (bearing ratio in %), only roughness peaks are removed. This results in an improvement in the tip height and micro-geometry of the component.

In contrast to polishing, the Superfinishing creates the cross-hatch that is common in honing. The cross-shaped indentations optimize the lubricant distribution and thus the emergency running properties as well as the tribological properties of the component. The tribological advantages reduce the friction and the energy consumption of the workpiece in use.

Our process creates a uniform, seamless finish over the entire surface. The desired micrograph is created using the tool oscillation and rotation speed of the component to be machined. Superfinish is not only suitable for finishing but can also be used before hard chrome plating to improve the surface quality of rotationally symmetrical components.

- Maximum dimensions: Ø 850 x 4000 mm

- Weight: max. 3000 kg

- Roughness: Rmax<0.1, Ra<0.01, Rz <0.1

- Bearing ratio Rpk, Rvk, Rmr depending on requirements

- Between peaks

High-gloss polishing

With the Superfinishing procedure, a surface quality up to high gloss can be created. Very fine finish tapes (up to 3 µm) are used for this purpose.

High-gloss polishing is required if the use of the component requires an absolutely homogeneous, clean and smooth surface. This is the case, for example, in the printing and foil industry.

- Maximum dimensions: Ø 480 x 3000 mm

- Weight: max. 2000 kg

- Roughness: Rmax<0.1, Ra<0.01, Rz <0.1

- Between peaks

Express service

For orders with increased deadline pressure, you have the option of using our express service. This is agreed upon in direct consultation with our production control and charged via a surcharge.

Initial sampling

Before starting more complex series, we offer you an initial sampling at discounted rates. Here you can convince yourself of the quality of our processing. In addition, together we ideally coordinate our production processes.

Tips for delivery

For optimum quality and short lead times in our production, the delivery condition of the components is one of the decisive factors. Here you will find helpful tips for the delivery of your components.